Industrial Track Lighting

busSTRUT allows for cost-effective lighting of an entire industrial space, flexible task lighting for an assembly area, and drop-down power.

busSTRUT allows for cost-effective lighting of an entire industrial space, flexible task lighting for an assembly area, and drop-down power.

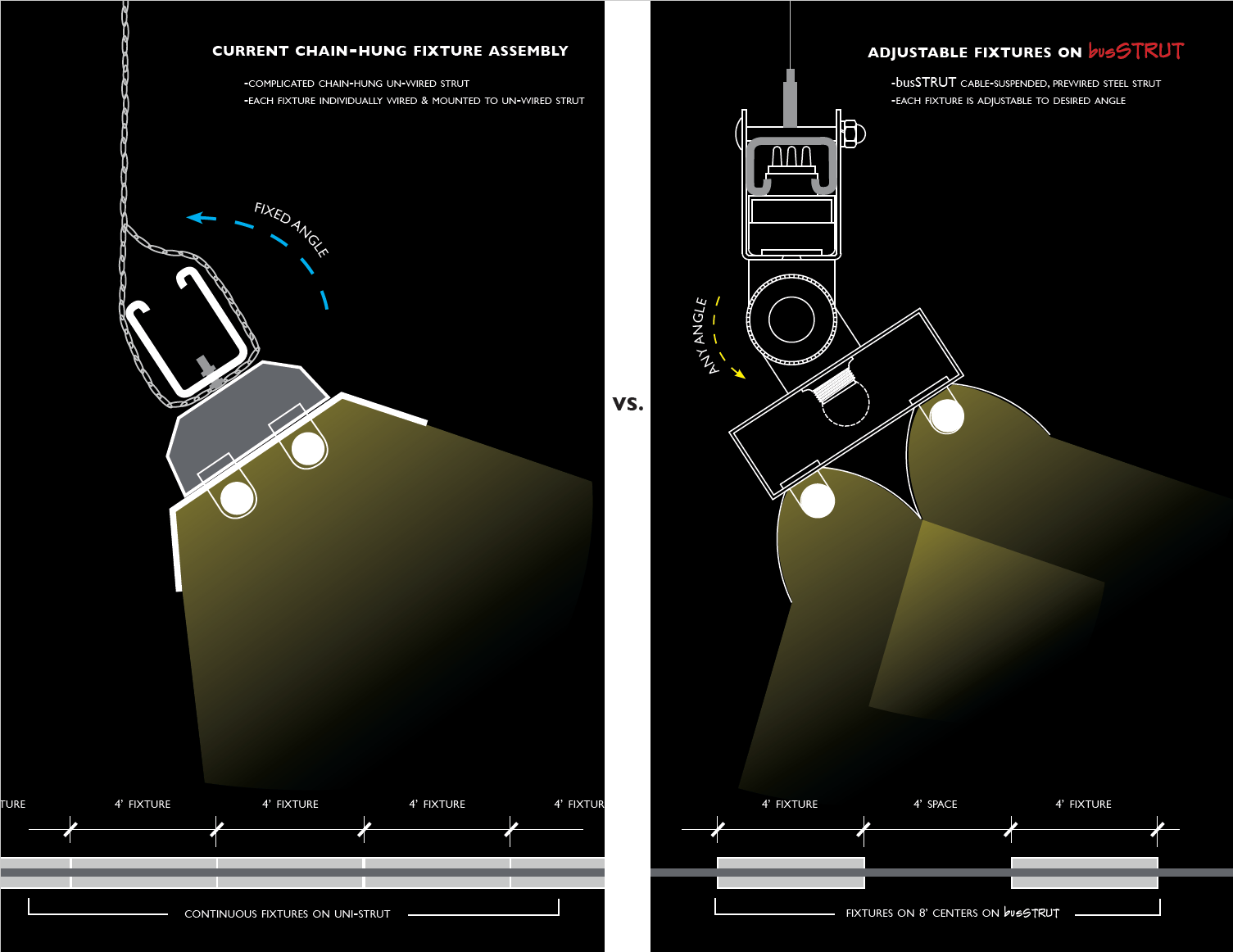

Installing high bays in industrial applications is typically accomplished by mounting fixtures from stems or chains. This is a time-consuming process that results in an unsightly maze of crooked fixtures. The busSTRUT system is engineered to simplify and streamline the installation process. busSTRUT is suspended from virtually invisible cables at the desired mounting height, allowing us to run parallel rows of busSTRUT-READY HIGH BAYS.

By resting a higher amperage double-deck column atop parallel rows of busSTRUT, we eliminate hand-wiring as well as a significant number of homerun feeds.

Installing task lights in industrial applications has traditionally been done with continuous linear lights, which are often difficult to install with a “tilt” toward the assembly lines. But with busSTRUT, you can now achieve noncontinuous “light-space-light,” and the fixtures can simply be tilt-adjusted when used over an assembly line.

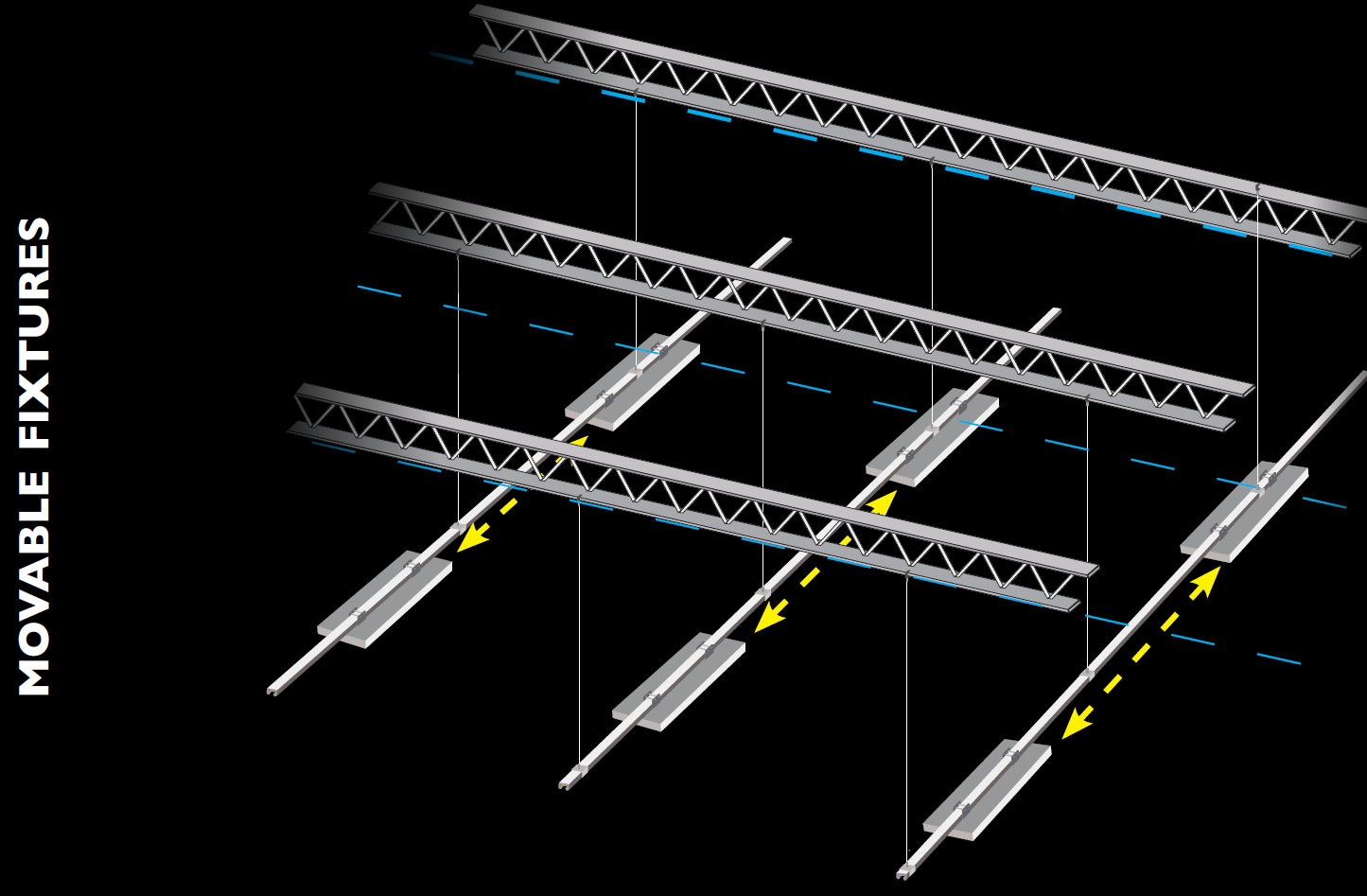

The busSTRUT system allows for the flexibility to add or move light fixtures based on what is being assembled below. If the industrial floor plan changes, so can busSTRUT.

busSTRUT is a busway, meaning that it can provide power to more than just lighting fixtures. With busSTRUT already overhead for lighting, power taps can easily be added to the system. Our power taps are attached to the busSTRUT via plug & play fitters, so power drops can even be moved or rearranged in the future!

Why endure the hassle of individually hanging and wiring each light fixture when there’s a smarter way? With busSTRUT, you can revolutionize your lighting installations. This system allows you to suspend pre-wired strut directly from the ceiling, onto which any light fixture can simply be plugged in and powered up. This means significantly reduced installation times, as there are fewer hang points and no need for separate electrical connections for each light.

Fewer Feeds with Industrial Track Lighting

busSTRUT TRUNKING dramatically reduces the number of homerun feeds required to power the lighting in an industrial facility. A 40amp run of busSTRUT supplies power to the 20amp branches throughout the configuration. The perpendicular run (trunk) of busSTRUT is powered by the homerun feed. From this trunk, intersecting rows (branches) of busSTRUT receive power via jumpers.

Flexibility with Industrial Track Lighting

Once busSTRUT is installed, lights can be mounted anywhere needed and without the concern of the structure overhead. busSTRUT provides unmatched flexibility to adjust, add, or remove lighting fixtures without the need for rewiring, making it a perfect fit for dynamic spaces that often require lighting adjustments.

Easily Re-Configure with Industrial Track Lighting

Unlike traditional pipe-and-wire systems, busSTRUT’s open slot accessibility to power allows for quick adjustments. Light fixtures on the track can be moved, added, or removed without the need for rewiring. This feature is particularly beneficial in dynamic industrial settings where the layout and lighting requirements may frequently change.

Task Lighting with Industrial Track Lighting

For industrial spaces that require lighting in certain locations to enhance productivity and ensure safety, the busSTRUT system offers the flexibility to precisely locate lighting where necessary. The busSTRUT system provides industrial spaces with unparalleled flexibility and control over their lighting environments, which is essential for detailed tasks and quality control processes.

Drop Power with Industrial Track Lighting

Leveraging the same infrastructure for both lighting and power enhances efficiency. With busSTRUT, the track not only supports various lighting fixtures but also serves as a conduit for electrical power. This integration simplifies the overhead environment by reducing the clutter of separate wiring systems and enhances the overall aesthetics and functionality of the space.